Wood fibre insulation

Welcome to Wood fibre insulation: The Energy Efficiency Podcast – episode 15, the podcast that brings you a mix of energy efficiency news, products and tips all year round. We’re interested in profiling people and products involved in promoting energy efficiency habits, products and information, so please do get in touch if you have something to contribute.

Secret sustainability

But before we get on with our advertised features, this week website Business Telegraph ran an article about companies keeping quiet about significant resource efficiency achievements, so-called “secret sustainability”. There are several reasons for this, including the fears of being accused of diverting attention from areas of their business that are less environmentally friendly, and customers worrying that the products will go down in quality or up in price, or both. It can also cause consternation along the supply chain, sparking fears of price rises or reduced orders of raw materials.

The article cites several examples of tremendous progress in resource efficiency in manufacturing. There’s an anonymous factory in Asia using only a single litre of water to make a pair of jeans (it doesn’t even tell the businesses it supplies about this extraordinary achievement).

There are the two wineries in Portugal that have silently switched to organic practices because they were worried about their health of their soil. They’ve swapped out pesticide and artificial fertiliser for technology and extra labour. Soil health, vine health and yield have improved, but they don’t mention it anywhere. Both wineries already had a good reputation and felt customers would perceive that the product had changed or was about to go up in price if it was suddenly labelled ‘organic’.

Greenwashing

Many companies have been accused of greenwashing, ie parading one area of their business that has a good environmental record in an effort to divert attention from less sustainable areas. Setting out with that intention is unattractive, but a business should be able to report good news for what it is.

The article in Business Telegraph suggests that companies don’t believe they’ll attract more B2B customers because, for example, they can make a car with a quarter the amount of energy they used to use. I question that. The article quotes Professor Steve Evans, of The Institute for Manufacturing at the University of Cambridge, as saying that businesses can’t accept that improved sustainability doesn’t mean an inferior product or increased price.

So it seems businesses divide into those who recognise the environmental and product and cost benefits of reducing resources, and those who see it as something a bit dubious with a negative knock-on for quality and cost. This is despite the Dow Jones Sustainability Indices repeatedly showing that the companies at the top of the range outperform those at the foot. It’s great to see that companies are making improvements, but roll on the day that those practises can be shared without fear of incurring a business disadvantage.

Wood fibre insulation

Over the last few weeks we’ve looked at sheep’s wool and Kingspan insulation. Today we turn our attention to wood fibre as insulation. Wood fibre has highly desirable properties for home insulation: it’s non-allergenic, renewable, durable, reusable and recyclable and in some cases compostable, and hygroscopic. This means it can absorb and release moisture without coming to any harm. However not all wood-based insulation is equal.

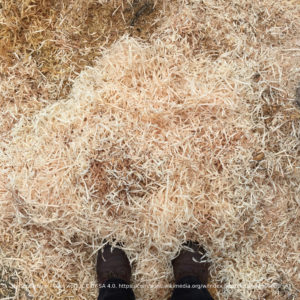

Sawdust and wood shavings

Once upon a time, some homes were insulated with sawdust and wood shavings, which were a straight waste product. These days however that doesn’t provide adequate insulation and as it compacts it becomes less and less effective. There any many newer wood fibre insulation products on the market, performing different functions and coming in different forms. They possess better elasticity than sawdust or shavings and so don’t compact as they absorb and release moistire.

Wood fibre insulation is a minimally-processed material that comes in loose little clumps that are blown into the area to be filled. Being loose, this form of wood fibre insulation can be forced into every little corner under appropriate pressure to keep thermal bridges to a minimum. This type of insulation performs extremely well – to quote SwedishWood.com it has “an almost unbeatable capacity to capture and store heat that is on the way out or in through the building envelope,” reckoning it’s about twice the capacity of mineral or glass wool. Our feature on passive cooling in ep 7 covered various methods of capturing excess heat during the day and releasing it during the cooler night time – this is a very simple method of achieving that.

This reminds us that insulation is not all about keeping cold spaces warm. Germany maintains an index of how various sustainable insulation materials perform in keeping a building cool in the summer. It has the snappy title of the German Association for Insulation Materials made of Sustainable Raw Materials. Wood fibre insulation comes out top in tests, with sheep’s wool about half way up.

Acoustics

Wood fibre insulation has impressive sound-dampening properties. It effectively reduces airborne sound – voices, traffic – and impact sound – footsteps, moving furniture. According to website backtoearth.co.uk wood fibre insulation is up to 12 times as dense as synthetic alternatives, which contributes to a quieter and more relaxed environment. Wood fibre insulation is also available as boards or varying densities and thicknesses, and are suitable as boards for underfloor heating.

Wood fibre insulation, like sheep’s wool, isn’t really flammable, which might be suprising. It chars, slows down the speed of fire and releases next to no harmful emissions. A good analogy is a book – page by page it burns swiftly, but try to set light to a whole book and it’s difficult to do. Unlike plastics woodfibre won’t drip blobs of flaming materials in a fire. In a timber-framed build this flame-resistance is a valuable property.

Pavatex

Pavatex is a Swiss company that has been making woodfibre insulation since 1932. When it opened a few years ago, the Pavatex factory in France was the highest-performing and most environmentally-friendly woodfibre production plant in Europe. Pavatex has received natureplus certification for its products. natureplus is described on the Alliance for Sustainable Building Products website as demanding “an above-average eco-balance, a maximization of renewable resources and a minimization of the use of petrochemical substances, very low emissions and the prevention of harmful ingredients.”

One Brighton, a building of mixed small apartments in Brighton, UK, included Pavatex in its build. It was chosen in part for its acoustic dampening properties, quite a consideration in a block of flats. The build met some opposition from designers, contractors and insurance companies who weren’t familiar with natural insulation, but to be fair this was nine years ago now so things should have improved. The developers had to seek formal approval on durability, and go to the Building Research Establishment for fire testing, backed up with case studies.

On-site things were easier, with the only slight issue being that Pavatex is less easy to shave or plane than polystyrene. All that required was the odd adjustment to render here and there. Builders found the woodfibre boards easier to fit than standard blockwork as no mortar is required.

In our feature on the poor energy performance of new builds we looked at the problems with poorly fitted plasterboard. Interlocking wood fibre boards avoid this problem. Although there was a slight cost increase with using wood fibre boards, the developers took that the view that it was more than worth it, especially in terms of the benefits it delivered for residents. Incidentally One Brighton was built with allotments on the roof for residents to grow their own food.

Winter ready

Our Ecoflap letter box draught excluder was a seasonal product, selling well over the colder months. We’ve discontinued it now – can you explain why?

Several reasons actually, some commercial, some design and some plain practical.

Retrofit

We had lots of people asking if we did a front facing version, as their letterplates were of a clam shell or clamp design that made fitting the Ecoflap more complicated, or their door’s crossbar was so narrow an Ecoflap couldn’t fit – they wanted a complete solution.

Some just had poorly fitted or faulty letterplates on an older door and wanted to make the howling gale go away. They found bolts and holes in doors with warped surfaces or the myriad sizes and forms of letterplates confusing and difficult to retrofit.

We also felt that as we tried to accommodate all these things the simple beauty of the design got lost. What should be a design classic was missing the mark trying to fit in with the past.

The point with draught proofing should be you stop the draughts at the outside not stuff up a hole inside resulting from poor design. We could have spent time and precious resources trying to improve it or we could put those resources to make a better letterplate which prevented draughts, reduced injuries from sharp edges and strong springs and stop shredding your post as it fights to get past all that.

Front letterplate

It’s not the first front letterplate we’ve developed. What’s the difference between the Letterplate, and the Letterplate Eco?

Our first attempt was a premium pure stainless steel design that was beautiful, worked brilliantly but did not work commercially. Our manufacturer struggled to meet basic standards of quality and finish and the resulting price per item was too high for a mass market product.

It was a shame to discontinue the Letterplate but it was so difficult to make that it just wasn’t feasible. The Ecoflap needed a facelift too. It didn’t have quite the aesthetic of the Petflap and the Letterplate. It did its job very effectively but it wasn’t a stylish an addition to the front door. It had to stick out on the door to cope with the wide range of sizes of letterplates, so was bigger than most people needed and to be honest, no, didnt look stylish.

Letterplate Eco

The Letterplate Eco will change that. It’s a complete change, looking at how to make it more widely available and keep it simple.

The design incorporates much that we have learned with our other key products the Petflap and the Ecoflap. As it opens from the front, it benefits from the full closing force of the wind and elements.

Using external grade automotive plastics means it is insulating, lightweight and corrosion free. The design has no metals or springs and is easy to recycle.

When will it be ready to buy?

We are switching our Petflap design on to full production and so our efforts can now be focused on getting the Letterplate Eco out in small batches ready for this winter. We will start with our material as shiny black finish just like the Petflap. We know we can technically make our products out of many materials for specialist supplies but the more affordable product will make a far bigger impact for people who really need that help keeping energy efficient.

Aims

There are a few elements to getting the house winter ready. The aim is to keep cold air out, keep warm air in, make the most of the heating fuel you use and avoid using energy to heat air that’s being cooled down by draughts. Sorting out infrastructural elements such as windows, insulation and boilers will make a big difference, but it’s not all about the big things. Stopping draughts coming in to the house is an easy way to make it more comfortable at an affordable price.

The government anticipates sizeable increases in electricity prices if we leave the EU without a deal. Even more reason not to waste any electricity.

Letterbox

The traditional trouble spots are the letterbox, keyhole, gaps around doors, catflaps, floorboards and chimneys. If the Letterplate Eco was available now we’d recommend that. We’ve had a development model on our front door for a year now and it’s working brilliantly. Our hallway is in the colder part of the house. The Letterplate Eco has just stopped dead the draughts that whistled in round the old letterbox. We didn’t have an Ecoflap, ironically, as we were among those people whose door’s crossbar was too short in height to fit one. We’re a great case study for the Letterplate Eco!

A Chubb-style keyhole can let through draughts, so be sure to fit a cover that won’t conduct cold air into the house.

Draughts can come in around doors. If your door just fits badly see if this can be addressed. If there’s a draught coming in under your door you can fit a weather strip to the foot of it. A stuffed fabric draught excluder is a very low tech but effective way of stopping a draught in its tracks. Fitting a thick curtain across a door will make a room feel more cosy and help to keep cool air from coming into the room.

Catflap

If you have a catflap that’s prone to staying open, rattling and leaking cold air, we have the solution. The Petflap is a draughtproof pet door that’s gentle on tails and paws. It has circular trunking so that it can be fitted into glass.

Cutting a square or squoval into glass is difficult. Cutting a circle is much easier, so we changed the shape of our trunking to accommodate that.

The Petflap won’t open or rattle in a draught because it’s always blown more firmly against its frame, whichever direction a draught comes from. We’ve had feedback from customers very impressed that it’s staying shut in exposed locations including Shetland. If a draughty catflap is a problem in your house, we recommend the Petflap.

Floorboards

Floorboards are another draughty spot, particularly in older houses. There are some pitfalls. The website DIYdoctor cautions against using expanding foam as, to quote them, “you will be forever cleaning up the mess”. Be aware too that whatever other method you use, it will be visible. Stain and wax won’t behave on the filler as it will on the floorboards.

There a few ways of filling gappy floorboards. You can put down a PVA layer and top with sawdust to the level of the floorbaords. This makes a PVA and sawdust goo that can be sanded when it’s dried. Pieces of wood can be fitted into the gaps then sanded to avoid any trip hazards. Flooring filler or decorator’s caulk is another option. There are also strips you can buy to push down between the floorboards. You have the option of a squashy strip or a V-shaped strip. Both are cut to length and pushed into the gaps.

Chimney

If you don’t use your chimney, you can stop it up with a Chimney Sheep. These are natural wool discs fitted to a handle, so that you can easily remove it if you do want to use your chimney. It doesn’t block air flow, but it does stop draughts whistling down the chimney.

There is one other place to check – anywhere cables come in to the building. Check there isn’t a huge gap around them and deal with any that are draughty.

Check your loft hatch too. A poorly insulated loft will get cold and that air can leak out round the loft hatch. That’s pretty simple to fit with foam strip. You can also fit an insulating material to the flat of the hatch to create a barrier to cold air.

Radiators

Now your house is draughtproofed you can look at how to maximise the heat you use. Radiator reflectors are very effective. They slip between the radiator and the wall and reflect warmth back in to the room. Use them on exernal walls or a shared wall in a terrace or semi-detached house.

I covered these in episode 2 of the pod. Radflek claims that its reflectors not only reflect 95% of heat back into the room, but reduce heat going out through the wall by 45%. The thing I particularly like about these is that they’re an unobtrusive fit-and-forget measure. The second your heating goes on they just start doing their job.

Raadiator reflectors are most effective in a house with poor insulation. You can use domestic foil instead although it’s flimsier and a bit harder to work with.

None of these measures will make you rich, but they will make your house that bit more comfortable over the coming months.

Energy efficiency in distilling

At the end of August the BBC ran a report on a distillery in Kirkwall on Orkney that is looking into powering its gin business on hydrogen power. In collaboration with Napier University and the European Marine Energy Centre (EMEC), the HySpirits project has received government funding to convert from LPG. It’s had £150,000, part of the government’s £390 million investment to reduce emissions from industry – I’m quoting from the government website here.

As we saw last week in the feature on hydrogen-powered trains, producing hydrogen isn’t always environmentally friendly, but the HySpirits project would use local wind and tidal power from the EMEC’s plant to make the hydrogen. Distilleries need to produce heat as part of the distillation process. There’s a link in the show notes to a Chemistry World feature on the science behind making gin, so head over there if you want to understand the role of heat in gin making.

If this project is succesful, The Orkney Distillery would reduce CO2 emissions by 86 tonnes a year, which according to gov.uk is the equivalent annual emissions from 10 homes or 18 cars – what size homes, how type of car?

Renewables

The Orkney Distillery is far from alone in wanting to reduce emissions. The Dalmunach Distillery near Aberlour runs its whisky distillery on wind and hydro power. Distilleries produce waste residues, and at Dalmunach both liquid and solid residues are converted to carbon neutral livestock feed and as a renewable fuel. The result is barely any waste. Dalmunach is able to return treated water to the River Spey.

Dalmunach is owned by Chivas Brothers, part of a larger drinks business Pernod Ricard. It’s the group’s most energy efficient disillery. Fortunately, unlike the businesses we heard about at earlier, Chivas is happy to report that Dalmunach uses nearly 40% less energy than the industry average to generate each litre of alcohol. Overall its water usage is 15% below the industry average. It’s working with Aberdeen university to improve its circularity.

Many elements come together to make gin and whisky distilling well-placed to promote and take advantage of energy efficiencies. Although whisky never goes out of fashion, gin has made a huge comeback in the last few years, especially among younger people, those who will have to suffer longest the effects of climate change and who are acutely aware of it. This forces gin makers to demonstrate strong environmental credentials. Gin drinkers are often looking for more than just a tasty drink – they want to know the back story. Gin makers rely on the botanicals that flavour the spirit, which connects them directly to nature. Whisky distilleries are in beautiful areas of Scotland (yes, Ireland and Wales too) and take their water from the local rivers. Whisky distilleries require a clean environment to produce a desirable product.

Bacardi

Beyond the UK, Bermunda-based Bacardi champions sustainability and has done since its establishment more than 150 years ago. It launched an environmental sustainability initiative called Good Spirited to see how it could reduce the impact of sourcing, packaging and operations. It intended to halve emissions by the end of 2017, but reached its target over a year early. It set itself stringent rules for obtaining sustainable, renewable or recycled packaging while not negatively affecting growers and suppliers. It’s constantly working to bring down the weight of its packaging, aiming for a 15% reduction by 2022. Water use and greenhouse emissions continue to come down, and Bacardi aims to send no waste to landfill whatsoever by 2022.

Laverstoke Mill

Bacardi has made changes in a number of areas of operation. It’s switched to biomass boilers at several facilities, using renewable organic material to fuel them. In Puerto Rico its Bacardi rum is produced using wind power, and its Bombay Sapphire gin is produced in a ‘green’ distillery. This distillery is at Laverstoke Mill in Hampshire. It’s an old paper mill on the River Test. There’s a video on the Bombay Sapphire website taking you through the curiously empty and quiet distillery, led by a CGI dove. It’s a lovely building and a rather soothing short video.

The facility was built five years ago and received the BREEAM award for Industrial Design in 2014. During construction Laverstoke Mill was the first distillery to receive an Outstanding at the design stage. What makes this distillery such an environmental success? It produces its own renewable energy from a solar array, and from a hydro-electric turbine in the River Test. It uses a biomass boiler fuelled by locally-sourced wood chips. The building incorporated building materials from demolished buildings. Throughout the site rainwater is harvested and flow restricted.

The distillery is in a Conservation Area and SSSI. Renovations had to work with this and has enhanced it. During construction fish and bats were temporarily rehomed, and bat boxes installed. Bats have access to roof areas. Derilict industrial buildings covering up the River Test were demolished. Aquatic plants were propagated in the river, there’s a fish guard in front of the turbine in the river, and no water is taken from the river.

It’s a fascinating site that’s been in use since well before the Norman Invasion. It pops up in Domesday and was turned into a paper mill by a Huegenot in 1719. It even printed watermarked banknotes for the Bank of England. The site has a tremendous heritage and it looks like Bacardi has gone to great lengths to preserve it.

John Dewar & Sons

John Dewar & Sons is part of the Bacardi group. Across its five distilleries, John Dewar & Sons has achieved reductions of 1/3 in greenhouse gas emissions, reduced water use by almost half, and reduced waste to landfill by 30%. It runs a blending and maturing warehouse in South Lanarkshire.

Bacardi invested heavily in Scotch whisky, in this case installing energy efficient conveyors to transport casks. Each of the 18 warehouses on the site can hold 72000 casks, so reducing the energy required to move them around will make big savings. Whisky is now moved between sites in tankers rather than casks, reducing annual CO2 emissions by 1000 tons, equivalent to keeping about 400 cars off the roads.

Wetlands

The site is planted with 130,000 new trees, planned with Scottish National Heritage. Rainwater is routed to a retention pond which provides wetlands for wildlife. This type of thing was first trialled by the Glengoyne Distillery. 12 wetland cells contain more than 14000 types of plants. Reed beds filter and cleanse effluent from the stills. After anaerobic fermentation the water is clean and can go back into the river without taking anything nasty with it. Treating the waste naturally means it doesn’t need to be transported off site.

In America, Marble Distilling, a distillery and bar in Colorado, put sustainability front and centre from the start. Instead of reusing an old building, the couple behind Marble distilling chose to build a new facility aligned with green building sepcifications. Now up and running, their distillery produces no waste. Like all distilleries, Marble uses lots of water. It designed what an article on popularmechanics.com describes as a “water energy thermal system”. Water is reused endlessly in a closed loop without losing any of its properties. The heat from the water is used in the building. They save millions of gallons of water this way every year and reclaim enough energy to power 20 homes.

Fortunately Marble Distilling is another company keen to share its achievements and best practice. Cheers to that.

Off grid energy access

Is off grid energy access your area of interest? If so you might be interested in next month’s Off-Grid Energy Access Forum 2019, on Wednesday October 2nd in London. It describes itself as “The only conference assessing global investment, market opportunities & technology developments for off-grid energy access at the last mile”. It looks at which technologies and business models are most effective in this area, how to meet growing power demand and develop customer relationships and how to add value to the projects. The link to register is in the show notes.

And what are we up to? We’ve made it into the press this week with a small piece in Real People. We’re working on the new batch and reservations are coming in steadily, so if you want one drop us a line at info@ecoflap.co.uk. Thank you for listening to episode 15 of the Energy Efficiency Podcast. Until next time you can find us on both Twitter and Instagram as Ecoflap, and on Twitter we also tweet as The Petflap. In next week’s episode we’ll look at: the VIBES awards, energy efficiency in policing worldwide, and the Dow Jones Sustainability Indices.

And what are we up to? We’ve made it into the press this week with a small piece in Real People. We’re working on the new batch and reservations are coming in steadily, so if you want one drop us a line at info@ecoflap.co.uk. Thank you for listening to episode 15 of the Energy Efficiency Podcast. Until next time you can find us on both Twitter and Instagram as Ecoflap, and on Twitter we also tweet as The Petflap. In next week’s episode we’ll look at: the VIBES awards, energy efficiency in policing worldwide, and the Dow Jones Sustainability Indices.

Music credit: “Werq” Kevin MacLeod (incompetech.com)

Licensed under Creative Commons: By Attribution 3.0 License

http://creativecommons.org/licenses/by/3.0/